How Is Linen Made From Flax?

Have you ever wondered why linens are so preferred? Unlike other fabrics, linen is the most preferred material because they are more comfortable. Linens are plant-based fabrics similar to cotton and involve a tedious process. However, countries like China manufacture linens in large quantities because of their unique characteristics. Hence, this uniqueness has made this fabric one of the most preferred materials. Thus, in this post, let’s see how linen is made from flax by hotel linen manufacturers in India.

Initial stage:

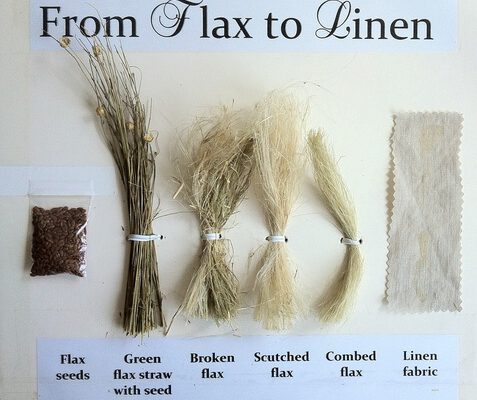

The foremost step involved in manufacturing the linen is sowing the flax seeds. These flax seeds are sowed in well-tilted and fertile soil during the coldest month of the year. Even some hotel linen suppliers in Chennai have land that is allowed to grow linen in large quantities. Once the flax seeds are turned into crops, they are pulled out along with the roots to obtain long fibers. These crops are then allowed to dry until the color changes.

Rippling and retting:

In rippling the dried flax plants are deseeded through a board filled with nails similar to a comb. So, the seeds are collected below allowing the flax to dry. Retting is the process where the inner stalk of the fiber is left to rot without damaging the external fiber, by using bacteria. But if left unattended for longer, it can damage the entire crop, so the crops are washed periodically for four to five days.

Breaking and combing:

The flaxes are then sent into a machine with rolling paddles, which breaks the crops and removes the fibers from crops. Now, the inner fibers are removed from the stalks, they can be combed into thinner strands.

Spinning and drying:

The thinner strands are spun using a foot-powered flax wheel or industrial machines. These are reeled into small bobbins under a hot and humid environment condition to ensure the flax doesn’t fall apart. Finally, the reeled yarns are dried under high temperatures. Thus, the hospital bedsheet suppliers in Bangalore supply only the ones that undergo these processes for their patients.

Weaving and bleaching:

It is the final process where the dried linen strands are weaved by interlacing in a weaving machine to form linen fabric. It is a typical weaving process involved where the lengthwise thread called warp is subjected to tension and another thread is allowed to pass through the warp is called weft. Thus, this process goes in cycles to separate the warp from weft. The color of the linen that is weaved is pale in color where the manufacturers bleach them to obtain white color.

Hence, these are the steps involved in making quality linens for every use. If you want to purchase the best linen, then purchase from KKR linens – hotel and hospital bedsheet manufacturers in the city for standard products.